We appreciate your interest and will get back to you as soon as possible to prepare a quote. In the meantime, feel free to discover more products on our website.

Product information

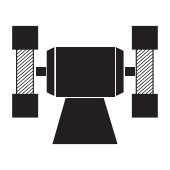

Description

The large dimensions of the PREMIUM flap wheels ensure long lifetime, continuity in machining and reduced durations of wheel changes. They are suitable for use on hand held machines with flexible shafts as well as on stationary polishing machines. The large diameter increases the contact area and creates a more uniform grinding pattern compared to similar tools with smaller dimensions, which also allows their use on large surfaces. Due to the arrangement of the flaps, continuous wear of the abrasive cloth and constant exposure of new grit is ensured, while maintaining a high and consistent abrasive performance throughout the life of the tool. The flap wheels combine flexibility with excellent adaptability to irregular contours. In addition, the strong ventilation during machining prevents overheating of the work surface, which offers excellent results in a wide range of applications. Abrasive flaps made of corundum cloth are fixed radially around the axis of the tool. The bore is reinforced by a metal ring with variable dimensions depending on the wheel diameter, which allows the wheel to be securely mounted on the machine. This is facilitated by an appropriate reducing flange.

Features

- Long lifetime and consistent results

- Reduced wheel change times

- Excellent grinding power

- Flexibility and adaptability

- Strong ventilation during processing, thus lower thermal load

Applications

- Finishing wide flat, concave and convex surfaces

- Grinding the internal and outer surfaces of tanks, containers and pipes

- Finishing parts of irregular shape such as handles, taps and moulded parts; removing and cleaning of welding seams

Recommendations

- When using flap wheels, the direction of rotation must be observed, which is determined by the side of the flaps with abrasive on the surface. In addition, it is necessary to work with low grinding pressure.

- The feed of the machined workpiece must be in the opposite direction to the direction of rotation of the wheel. If used incorrectly, the performance will be reduced and there is a risk of wheel breakage.

Download Hub

Flyer

- English (US)

Recommendations